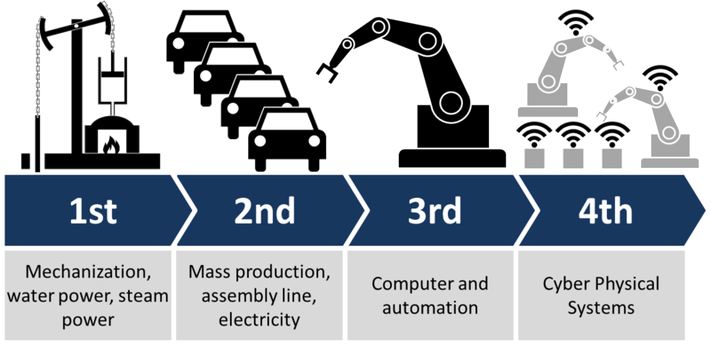

Revolutions in the Manufacturing Industry

The Fourth Industrial Revolution, or Industry 4.0, is extremely important for the manufacturing sector. It represents the next era of technology with the best quality, productive and efficient manufacturing. One who failed to adopt Industry 4.0 will not survive in the market and cause organizations to fall behind. But before understanding what, why, and how of Industry 4.0, it’s beneficial to know about the revolution in the manufacturing industry since the 1800s. Our world has experienced four different revolutions in the manufacturing industry and is still experiencing today.

The First Industrial Revolution

Before the 1800s, manufacturing was performed by human beings with the help of animal power. After the First industrial revolution, in the early 1800s, the manufacturing process evolved to a more optimized way. Some basic machine tools had been designed which were driven by a water/steam power engine.

The Second Industrial Revolution

The second industrial revolution happened in the beginning 20th century. In this revolution, electricity was introduced in the industries which enabled the manufacturers to increase efficiency. Electric machinery was much more portable than steam engine driven machines. Mass production through assembly lines was also introduced during this revolution.

The Third Industrial Revolution

The world entered slowly in the second industrial revolution in the late 1950s. Electronic and Computer technologies were introduced into the factories. During this phase of revolution, industry was experiencing a shift from analogue to digital technology and automation.

The Fourth Industrial Revolution, or Industry 4.0

A fourth industrial revolution has emerged from the past few decades which is also known as Industry 4.0. In this revolution, the manufacturing sector moved towards digitization that involves comprehensive interaction/interfacing between various modern technologies such as Internet of Things (IoT), cyber-physical systems, big data, advanced analytics, human-machine interfaces, cloud computing in real-time which offers a holistic approach to manufacturing. It connects physical with digital, and allows for better collaboratio.

Hence, Industry 4.0 enables entrepreneurs to more readily control and see each part of their activity, and permits them to use moment information to support efficiency, improve cycles, and drive development.

Written By:- Mr. Prashant Bhardwaj, Assistant Professor Department of Mechanical Engineering Manav Rachna University